Heavy Duty Shut Off Dampers and Weather Louvre at BD Medical, Swindon

Located in southern England, BD Medical is a global medical technology company that

is advancing the world of health by improving medical discovery,

diagnostics and the delivery of care. BD leads in patient and health care

worker safety and the technologies that enable medical research and clinical

laboratories.

Working closely

with our client, HVC supplied various products to help provide ventilation

solutions in cleanrooms and controlled areas at BD Medical in Swindon.

The client’s

specifications meant that HVC were asked to supply new volume control dampers

to replace existing dampers that supported the surrounding air handling units

by assisting the air side economisers in the change from re-circulation to free

cooling mode.

By having an air-side

economiser, BD Medical are able to supply cooler outdoor air into the building

which reduces or eliminates the need for mechanical cooling during mild or hot weather. This leads to a lower energy consumption, improved indoor air quality

and in-turn reduces energy costs. This was essential at BD Medical as the

medical plant runs 24/7 all year round apart from the Christmas shutdown period

In an air-side

economiser system, dampers are used to regulate the amount of air introduced,

recirculated or exhausted from the building. Such a system, therefore required

a volume control damper that had proven low leakage rate and the ability to

cope with high velocities.

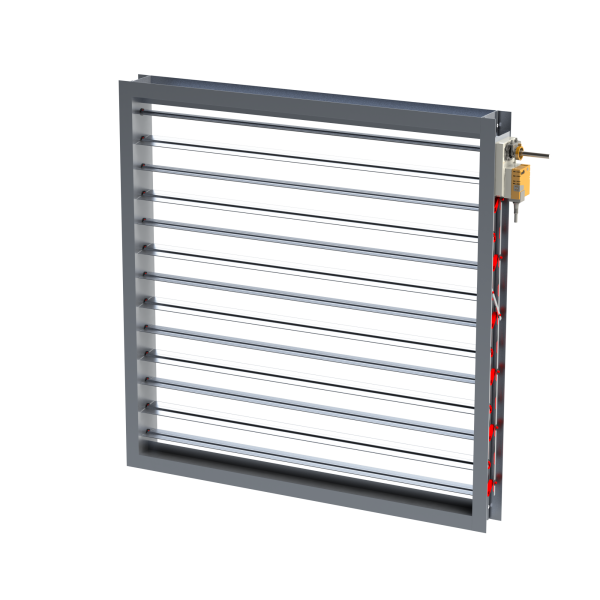

HVC responded

by supplying our new S800CA heavy duty low-leakage shutoff dampers.

The advantage

of us supplying our Series 800CA is that this specific damper has a very low leakage

rate. The damper is designed to be fully sealed making use of silicone rubber

blade edge seals, stainless steel side seals and EPDM rubber stop gap seal to

aid in reducing leakage.

This damper is

also ideal for this project due to its suitability for high airflow velocities being

introduced, recirculated or exhausted from the air-side economiser. This is

down to the unit’s robust construction which utilises a 180mm deep galvanised

frame, extruded aluminium aerofoil blade and steel drive system.

Our Series 800CA also has a minimal resistance to airflow when open, with the large 150mm blade pitch producing a free area of up to 80%, something of importance in this installation.

We supplied 14

dampers for this project which ranged in size from smaller units at 575mm x 575mm up

to larger units at 1500mm x 740mm, all of which were made in a single section. S800CA’s are available in sizes up to 2m x 2m in one section. These specific dampers only

required rectangular connections to suit matching ductwork, however circular

and flat oval connections are also available.

All dampers were factory fitted with Belimo SM24A-SR motors; however, we offer a

full range of motors.

The client

mentioned that both “Air Ducts (Southern) Ltd and their client were very happy

with the S800 dampers we supplied and that they are a massive improvement on

the predecessor”.

HVC also

supplied a small quantity of our Series WL75 weather louvre. The application

required a 3m x2m rectangular fixed blade louvre to be installed in the

external wall on the first-floor plantroom for the fresh-air intake for one of

the air handling units. HVC were able to make such a louvre in 2 sections,

providing an stainless steel insect mesh to suit and a finish which married up

with the existing façade.

All of the above

was manufactured and delivered by our hard-working team at HVC supplies. We

worked within the time frames given by Air Ducts (Southern) Ltd to enable them

to work efficiently during the Christmas shutdown period.