Weather Louvre Testing: What is EN 13030?

EN 13030 is a harmonised European standard that specifies a method for measuring the performance of louvres under simulated rain and wind pressures, both with and without airflow through the louvre under test. This standard provides a common basis for comparing the performance of weather louvres of different designs using two defined performance criteria.

Manufacturers wishing to test louvres against this standard typically supply a 1m x 1m sample for evaluation to a suitable test house, such as BSRIA, based in Bracknell, Berkshire.

Performance Criteria for Louvres Evaluated Against EN 13030

1. Resistance to Ingress of Simulated Rain

This aspect of the standard measures how effective a louvre is at removing simulated rain (75 l/h) from an airstream when subjected to a constant wind speed (13 m/s) and various airflow rates (0 m/s to 3.5 m/s in 0.5 m/s increments). The effectiveness is classified as follows:

Class A - Excellent: 99% effective and above, ingress up to 0.750 l/hr/m²

Class B - Good: 95% to 98.9% effective, ingress between 0.751 l/hr/m² and 3.750 l/hr/m²

Class C - Fair: 80% to 94.9% effective, ingress between 3.751 l/hr/m² and 15.000 l/hr/m²

Class D - Poor: Less than 80% effective, ingress greater than 15.000 l/hr/m²

2. Coefficient of Entry/Discharge (Ce/Cd)

This aspect of the standard measures how much resistance a louvre presents to airflow, categorised as follows:

Class 1 - Excellent: Ce of between 0.4 and 1.0

Class 2 - Good: Ce of between 0.3 and 0.399

Class 3 - Fair: Ce of between 0.2 and 0.299

Class 4 - Poor: Ce of 0.199 and below

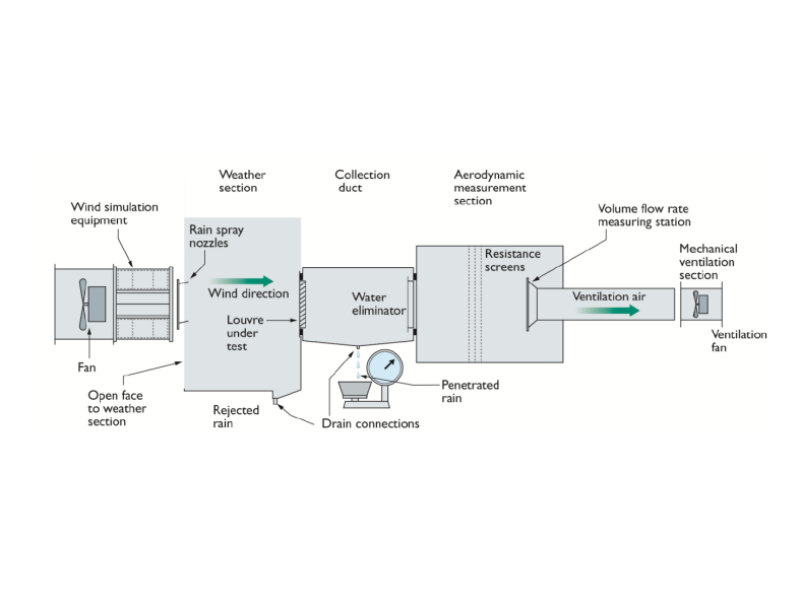

Understanding the EN 13030 Testing Process

Testing a louvre against EN 13030 involves two main tests:

1. Water Penetration Test

- The weather louvre is subjected to fan-driven wind at a speed of 13 m/s and sprayed water simulating rainfall at a rate of 75 l/h.

- Air is drawn through the louvre at various set velocities (0, 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, and 3.5 m/s).

- Each test begins with a pre-test soak of about 30 minutes and runs until results stabilise or for a minimum of 30 minutes.

- Penetrated water is collected, measured, and recorded over time to provide the characteristic curve for the test louvre.

2. Pressure Drop Test

- The louvre is mounted in the upstream opening of the Aerodynamic Measuring Section (AMS).

- Pressure tappings in the plenum walls of the AMS measure static pressure during testing.

- Airflow volume is calculated from the differential pressure at the measuring cones, ensuring even flow through the cones for accurate readings.

- By adjusting fan speed, the total airflow through the system changes, varying the pressure on the louvre under test.

- Measurements are taken to provide the characteristic curve for the test louvre.

-

Contact HVC Supplies for Expert Advice

The Importance of EN 13030 Testing

Testing a louvre against EN 13030 provides a grading against the two performance criteria mentioned above. Understanding the specific performance requirements for any application is crucial to ensure appropriate louvre selection.

At HVC Supplies, we offer one of the widest ranges of louvre systems available from any UK manufacturer. Our range is constantly expanding to meet new industry requirements and customer demands. Online, you will find a full range of louvre systems, from basic single bank weather louvres to Class A-rated high-performance louvres and sand trap louvres. With a dedicated design team working on both new developments and bespoke projects, why not try HVC for your next project?

For further information about our product range or to learn more about our certifications, please get in touch with us today. Our team of experts will be happy to answer any questions you may have.

-

Downloads